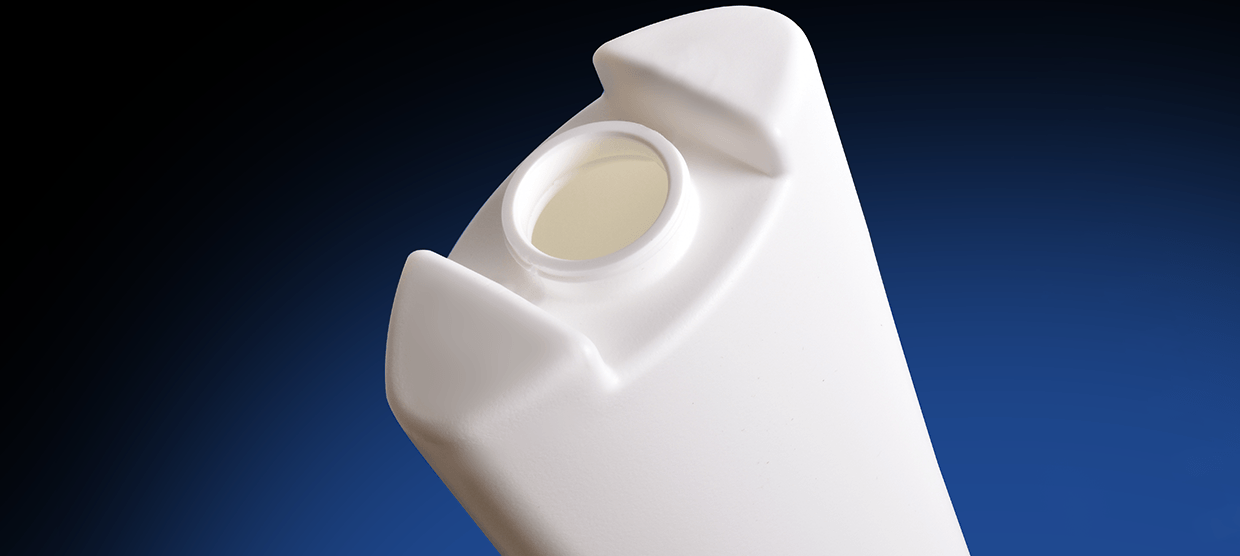

Extrusion Blow Moulding

Extrusion blow moulding (EBM) is a highly versatile process that can provide unique shapes, sizes and neck types, using a variety of plastics. This versatility gives an overwhelming advantage over other

bottle manufacturing processes.

One of the most common resins used in the EBM process is HDPE (high density polyethylene). Although semi-opaque in its natural state, a high gloss feel and appearance can be achieved if required. Similarly, a more squeezable feel can be achieved using MDPE (medium density polyethylene), making it ideal for products such as creams and lotions.

Packed with Sustainability

HDPE is one of the most easily recyclable materials for brands seeking Post Consumer Recycled (PCR) options, with varying degrees of recycled HDPE content available, from 10% to 100%. The EBM process is also ideally suited for bioplastic, which uses ethanol from plant-based materials instead of fossil-based materials such as oil or gas.

Need an Environmental Solution?

The Interchangable Flexible Moulding Process

One of the many benefits of the extrusion blow moulding process is the flexibility to change necks without having to change the entire mould. This customisable solution enables customers to use differing neck fitments on the same bottle mould, eliminating the need for a completely new mould each time. This can provide a compelling proposistion for brands seeking a more cost effective moulding solution.

What are the benefits of the Extrusion Blow Moulding Process?

Can be moulded to produce complex shapes and sharp contours

The process produces bottles with a high stiffness

Polyethylene materials offer a good resistance to water vapour

Provides excellent resistance to alcohol, acid's and alkali's

The process allows for interchangeable neck moulds

Extrusion blow moulded HDPE bottles can be easily recycled