Recycled Solutions

Plastic products that have completed their life cycle as an everyday consumer item and then been recovered from waste are known as post-consumer. The post-consumer recycled (PCR) plastics most commonly used for packaging derive from PET & HDPE products such as clear drinks bottles and more opaque milk bottles.

Widely accepted at most recycling centres, PET and HDPE are the two most accessible plastic polymers to repurpose, benefitting from the most developed collection and recycling systems.

As these systems continue to develop and material technologies advance, brands are able to reduce virgin polymer content in their products by combining virgin and recycled materials at varying levels. However, increasingly, more and more brands are going one step further with recycled content rates up to 100%.

What are the benefits of recycled materials?

The use of recycled plastics helps reduce overall virgin plastic consumption

Enables waste plastics to be be recycled into new and useful products

Redirects discarded items away from landfill or the environment

The use of recycled content helps lessen harmful greenhouse gas emissions

Recycled plastics do not require any further depletion of new fossil fuels

The use of recycled content can help society adopt a circular economy

Consumer engagement benefits

Increased consumer awareness over recent years has fueled public demand for recycled packaging. This demand provides genuine opportunities for brands to share their environmental values, build brand loyalty and change perceptions with their consumer.

When you use recycled content in your packaging, it can demonstrate voluntary responsibility around supply chain practices, which shows genuine, responsible leadership.

As environmental awareness increases, there is growing consumer support for brands that implement responsible business practices. When brands use environmentally-friendly packaging, it creates an empathetic connection with consumers who care about their purchases’ environmental impact.

PCR35 – our new environmental standard

In April 2022, a new tax will come into force aimed at increasing the minimum level of recycled content in plastic packaging to 35%. As a responsible manufacturer and an established champion of recycled plastics, Spectra supports the new move and has already put in place measures for the new policy with the rollout of our new PCR35 initiative.

PCR35 will see all new quoted projects include a minimum of 35% PCR as standard. Any customers not wanting 35% recycled content will need to advise us on their opt-out wishes. PCR35 follows our successful PCR10 initiative, which was launched in 2018 to widespread customer support. PCR10 provided the perfect launchpad for brands looking to embrace recycled content, and we anticipate this new environmental standard will further incentivise others to ramp up their responsible packaging endeavours for the good of the environment.

Manufacture

The bottles are made in our factory in Halesworth. The bottles are blow moulded from either PET or HDPE, while closures are injection moulded from PP plastic.

Consume

Once manufactured, the finished packaging is retailed for use to the consumer.

Discard

Once consumed, the used packaging needs to be discarded responsibly to ensure the correct waste stream is used so that it can be recycled.

Collect

There are several methods for collecting recyclable plastics. These can include kerbside collection as well as drop-off centres, and deposit or refund programs. After collection, the waste materials are transported to a recycling facility.

Sort

Once at the recycling facility, materials are sorted, usually by type of plastic, colour or even by how the original material was made. This is important because different types of plastics must be processed in different ways, with some recycling facilities only capable of recycling one kind of plastic.

Grind

The plastics are ground up into small pieces which allow for any remaining impurities to be washed away in the next process.

Wash

Plastics must be washed before the process can continue. This is to ensure the removal of traces of dirt and contaminants before the next stage of the process.

Dry

Once the plastics have been washed, a drying process needs to be carried out prior to the flakes being pelletised.

Pelletise

The final step is when the plastic particles are made into recycled materials used for future production, otherwise known as compounding. The small particles are crushed and melted together into plastic pellets, ready to be used again in the production of more plastic products.

Understanding open and closed loop recycling

What is closed-loop recycling?

Closed loop recycling means a product is recycled into another, almost identical product. For example, recycling a PET cosmetics bottle into a new PET cosmetics bottle. Closed-loop recycling also ensures your bottle can be made into new bottles rather than end up in landfill or the environment. This process presents many environmental advantages, including preserving natural resources, reducing the risk of harm to the environment and wildlife and minimising pollution and the use of new raw materials.

What is open-loop recycling?

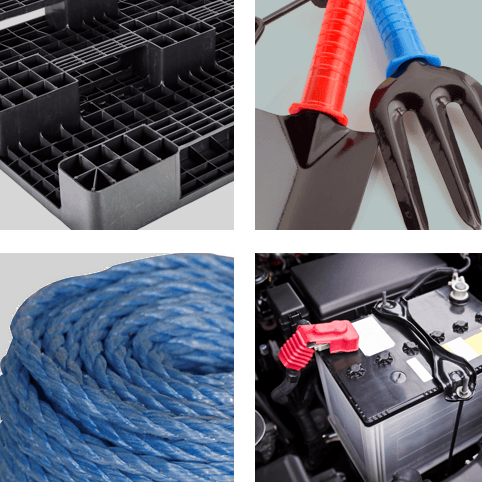

Bottles that include high levels of colouring or labelling, will not be recycled back into new bottles. However, far from assuming that this then consigns them to landfill, items such as these can be recycled back into something else that would otherwise be manufactured from virgin plastics. Similarly, when polypropylene (PP) closures are screwed or snapped back onto bottles before being put into recycling bins, they can also be recycled into other useful products. This type of repurposing is commonly referred to as open-loop recycling, or sometimes secondary recycling or downstreaming.

Open loop applications – life beyond your bottle

The importance of open-loop recycling cannot be underestimated. The process enables more and more plastic items to be repurposed into many different end products. It’s important to stress that these products would need making regardless, and open-loop recycling ensures they are not made solely from virgin materials but contain recycled plastics.

By turning products into something other than what they were before, the possibilities for recycling expand significantly. This is because open-loop recycling helps us get more from old plastic products, effectively giving them another life beyond their conventional life span.